VSP-G1 User Manual: Difference between revisions

| Line 274: | Line 274: | ||

|Toxicology||Testing the toxicology of nanoparticles can be made faster and easier using spark discharge. | |Toxicology||Testing the toxicology of nanoparticles can be made faster and easier using spark discharge. | ||

|} | |} | ||

''Above table based on data | ''Above table based on data searches using [https://www.scopus.com/ Scopus.]'' | ||

</blockquote> | </blockquote> | ||

Revision as of 10:58, 13 October 2016

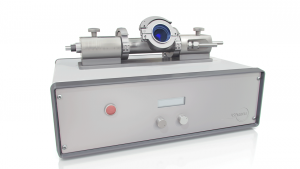

This is the comprehensive User's Manual for the VSParticle Generator One Spark Generator (VSP-G1). The Quick Start Guide is available as a quick reference for standard operation and maintenance of the VSP-G1 unit.

VSParticle

Molengraafssingel, 10

2629JD Delft

The Netherlands

info@vsparticle.com

www.vsparticle.com

(Ask TC about adding an infobox to the right side... see written notes for content layout)

Introduction

The VSParticle Generator One Spark Generator (VSP-G1) is designed for researchers ("operators") studying material properties who want to easily produce inorganic nanoparticles from conductive materials. Ease of use allows the operator to control the size of nanoparticles (1 atom to 20 nm) and production rate (xx – xx). The operator can use different gases and electrode materials, comprising pure or composite materials, for a wider range of combinations. The closed system is designed for high purity with an inner chamber containing no polymers near the ablation zone. Gas-based production eliminates the need for chemicals/surfactants or precursors. The reactor can easily be customized to allow cross flow, co-flow, through flow (standard) and combined configurations.

The production rate depends on the energy input into the spark, and material properties of the electrode. The VSP-G1 has a maximum operating power of 60W, which corresponds to ablation rates up to ~100 mg/h for e.g. Au. Particle size is a function of the production rate and the flow rate. The spark gap is controlled automatically, allowing continuous operation. The spark generator is designed for a broad operating window, making it suitable for applications ranging from cluster research to materials science.

The closed system provides a safer production of nanoparticles and can easily be dismantled for safe transport of produced nanoparticles as well as for system cleaning and maintenance. Periodic cleaning and replacing of electrodes can be easily performed by the operators with a safe, simple and fast (<20 mins) protocol.

The output of the system consists of a gas stream filled with particles, with no polluting by-products formed during production. The particles are made available as an aerosol, allowing the operator to choose a suitable deposition method for his or her substrates. VSParticle can help select/develop a deposition system fitted to your specific needs.

The portability of the VSP-G1 system allows it to be integrated into a larger system for more complex operating procedures.

How to use this manual

This user's manual provides instructions for the set-up, installation, operation and maintenance of a VSP-G1 unit. Before operating the VSP-G1 unit, please read the manual with careful attention to the safety section and to the warnings provided throughout the manual, indicated by the following symbols:

Warning information.

| (Short index of manual and a 1 sentence summary of each chapter/section) |

A quick start guide is also included for faster set-up as part of the standard operating procedure. For more information regarding safety and more complex operations as well as troubleshooting and maintenance, please refer to this manual.

System and Operator safety

top [Use this as part of a general introduction in the appendix. The introduction in the User's Manual should be/comprise a summary of that appendix]

Aerosolized nanoparticles are formed in a spark generator after a high voltage spark evaporates part of two metallic electrodes. This method is flexible with regards to the composition of the nanoparticles. The resulting nanoparticles are carried in a flow of gas, where they can be manipulated and/or transported, before depositing them onto a substrate.

The G1 spark generator is designed as a continuous source of aerosolized nanoparticles for use in a controlled process system. This controlled process system typically comprises a gas source, a gas tight system of unit operations, valves and tubing, and a gas exhaust fitted with one or more particle filters. Typical conditions in the process system are room temperature and ambient pressure. The system can be run at slight over- or under-pressure.

Intended use of the VSP-G1

Do not exceed +0.3 barg. Do not turn on the spark below -0.3barg.

Do not exceed +0.3 barg. Do not turn on the spark below -0.3barg.

Intended use of the VSP-G1

The G1 is not intended for use with reactive gases, in particular gases containing more than a few percent oxygen, such as air.

The G1 is not intended for use with reactive gases, in particular gases containing more than a few percent oxygen, such as air.

The risks associated with a spark generator can be divided into two categories: those associated with the machine itself, and those associated with the nanoparticles. Machine-related risks are more widely regulated by international norms, such as the European conformity system required for marking certain products with the CE symbol. Synthesized nanomaterials are relatively new and their quantum properties are still being studied. For this reason, nanomaterials are precautionarily considered highly toxic materials. Due to the fact that little is known about nanomaterials, safety measures for working with, storing and transporting nanoparticles have been primarily drawn from those designed for fine particles.

Safety of machinery

The VSP-G1 spark generator comprises general electronics (<50V), gas connections and high voltage (6kV), as well as moving parts. Several safety mechanisms mitigate the risk for damages and incidents related to potential equipment failure, but primary responsibility for correct and safe operation lies with the user of the system. The VSP-G1 is intended for use by qualified personnel only.

Operator safety actions

The operator is required to ensure that:

- the reactor is correctly mounted (see flow configurations); set hyperlink

- there are no objects near the electrodes (see flow configurations); set hyperlink

- process connections are correctly made (see process connections); set hyperlink

- the pressure in the system is limited to 0.4 barg (see process connections); set hyperlink and

- all, if any, external safety systems are functional (where applicable)

- personal protective equipment are being used correctly (gloves, glasses, and FFP3/P3 certified filter mask).

Safety mechanisms

Interlock.

The interlock cuts power to the high voltage supply and the motor, shutting down particle production.

Gas connections and other user-provided functions are not controlled by the interlock.

Gas connections and other user-provided functions are not controlled by the interlock.

Clearing interlock. To clear the interlock state, the operator must first fix the conditions that caused the state change. Afterwards, press and depress both dials to clear the interlock.

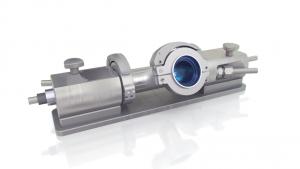

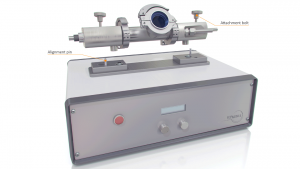

Reactor interlock. The VSP-G1 detects whether the reactor endcaps are properly mounted. The operator must ensure that the reactor itself is correctly assembled. In short, this means that the reactor is leak-tight and the exposed electrodes and electrode tips are free to move with a minimum clearance of 10mm from any foreign objects.

External interlock. (option) An external interlock switch can be provided for incorporation in an external safety system. To allow operation, two pins of the interlock connector must be connected (shorted). Breaking the connection switches the system into interlock mode.

Other residual risks

Pressure. Pressure within the closed system poses a serious risk when improperly handled. Increased pressure can be caused by unintentional release of gas at high pressure, the closing of output valve while the input valve is open, clogged filters, (etc?). If the pressure within the system were to reach 1.4 bar (0.4barg), seals could be compromised or the viewport could explode..

Non-ionizing radiation. The spark plasma emits a bright light in the visible and UV range. A viewport with a removable optical filter is included to allow visual inspection of the electrodes. Additionally, electromagnetic radiation (radio frequency) may be emitted.

Avoid damaging your eyes. The optical filter is designed to protect against the intense light of the spark. Do not remove the optical filter when running the spark.

Avoid damaging your eyes. The optical filter is designed to protect against the intense light of the spark. Do not remove the optical filter when running the spark.

The VSP-G1 comes with a specially coated viewport to screen electromagnetic radiation. Do not scratch the coating (see maintenance). Do not replace the viewport with a different type.

The VSP-G1 comes with a specially coated viewport to screen electromagnetic radiation. Do not scratch the coating (see maintenance). Do not replace the viewport with a different type.

Noise emissions. When operating under full power, the VSP-G1 can generate noise levels up to TBD dB. MEASURE AND DETERMINE RISK.

Safety of nanoparticles

Because our spark generators can in principle be used to produce nanoparticles from any metal, we start from the assumption that they pose potential risks to the health of operators, consumers and to the environment. This manual addresses operator exposure. Consumer exposure is determined by the application in which the nanomaterials are to be used, and should be evaluated on a case-by-case basis by the user. Environmental considerations should also be addressed by the users with a life cycle analysis, briefly discussed below.

The main channels of user exposure to nanoparticles are through absorption, ingestion and inhalation. The aerosol nature of the produced nanoparticles by the VSP-G1 system presents more risk of exposure through inhalation. The respiratory system of the human body has natural defenses in place for airborne particles such as dust, viruses and bacteria, however, nanoparticles are able to bypass most of these defenses due to their small size. For this reason, nanoparticles are treated in the same way as fine particles. (see the end of this section for links to further information on health safety)

Operator exposure While the VSP-G1 unit is designed to be a closed system to maximize safety when working with nanoparticles, there will be situations in which it will be necessary to open the system, including routine maintenance activities, replacement of electrodes and filters, and sample extraction. The list below also includes some possible situations in which the operator may be inadvertently exposed to nanoparticles and a brief summary of the necessary precautions to prevent, wherever possible, such situations.

Life cycle analysis

The waste of the spark generator consists of the carrier gas plus any nanoparticles not deposited on the substrate but picked up when cleaning the reactor surfaces and the pre- and end-filters. These materials should be pooled, preferably separated by the elements in the waste, in order to recycle the metals. The carrier gases are typically inert Ar and N2, which can be vented (e.g. through a fumehood). If other carrier gases are used (toxic, greenhouse, etc), capture or post-treatment should be used to conform to general industry or laboratory standards on gas use.

Life cycle analysis for the end product should be evaluated by the user of the technology on a case-by-case basis.

Links to more information:

- Health Significance of Nanotechnologies, a report produced by the Health Council of the Netherlands in 2006

- Nanosafety Guidelines, a set of safety recommendations for working with ‘free nanostructured matter’ in research activities conducted within Dutch Universities

- Nanosafety Quick Check, a checklist developed based on a summary of the Nanosafety guidelines listed above is there a link to this, or can we provide this as a downloadable file? permissions?

System Description

What's in the box

- VSP-G1 Unit:

- Reactor

- Base unit with reactor mount

- Cu electrodes

- Cables

- Quick Start Guide

- EC Declaration of Conformity

- Warranty

Mount tool

Reactor

Base unit

Cables

Setting up

Foreseeable misuse: xx

Setting up the base unit

Assembling the reactor

Electrodes

Mounting the reactor

Stability conditions: * xx * xy *xz

Process connections

Flow configurations

Final set up checklist

Operating the system

Standard procedures

(text becomes foundation of quick start guide... link also to quick start guide like this: This section is also available as a Quick Start Guide. (hyperlink))

Pre spark procedure

- System is leak-tight

- An appropriate filter has been installed (HEPA or better)

- Overpressure protection is in place and functioning

- Check that all electrode connections are ok

- Make all the necessary modifications and settings (confirm this is correct with Tobias)

Post spark procedure

- Stop particle production

- Flush system (9x of the system volume)

- Close off gas source

- Contain the (to be) exposed area

Retrieving the produced nanoparticles

Manual controls

Atypical situations

System care

Maintenance Protocols

Regular use

Periodic maintenance

Safe handling and storage

Possible ways to make the system safe before opening

- xx

- yy

- zz

Safe transportation

Troubleshooting

Error messages and how to resolve them

Common issues and how to resolve them

When to contact VSParticle

(text box with contact information)

Accessories and Replacement Parts

top

Electrodes

Appendices

Theory/Background

Overview of nanoparticle research

Due to unique quantum properties and the increased reactive nature of nanoparticles, their usages have immense applications within the fields of Physics, Biology and Chemistry, producing new areas of study centered around their successful applications.

There are six major areas of scientific study that have been studying the application of nanoparticles (FOOTNOTE: compiled using the Scopus database https://www.scopus.com/): Catalysis, Sensors, Electronics, Coatings, Energy and Health. The highest number of publications are from the fields of Catalysis, Energy and Health. Energy research contains the most subfields. Another area not as widely studied as the six mentioned above includes the application of nanoparticles in lubrications to improve lubricant performance.

The subfields of nanoparticle application research within the six areas include:

Catalysis New catalysts Atomic mixing enables the creation of completely new alloys and materials with improved catalytic activity. Impregnation of supports Spark discharge can be used to impregnate nanoparticle-sized catalytic support, which greatly improves surface area and has already been applied in catalytic converters in cars. Sensors DNA/RNA detection By attaching small pieces of DNA or RNA to a MNP, the complementary piece of that DNA can be detected, which is useful in medical diagnostics or genetic modification. Gas sensors Sensors can be made much more sensitive by using MNP's and can be applied to many gases. Bio-sensors MNP's can be used to improve bio-sensors that detect organic compounds. Electronics Printed circuits MNP's can be deposited in a pattern or lines to create electronic circuits. Flexible electronics The circuits are thin enough to be flexible and can be deposited on any surface, even fabrics. Photodetectors ( ) Coatings Functional coatings Surfaces could be modified with MNP's to create a transparent, functional coating, which could produce energy, be self-cleaning or be hydrophobic. Anti-corrosion coatings Depositing layers of AlO makes the underlying metal more oxidation resistant. Energy Fuel cells Integrating Pt or Pd NP's as catalysts in fuel cells could make them more efficient. Solar cells Using quantumdots in solarcells could make efficiencies possible above 40%. Water splitting Gold MNP's can improve photochemical water splitting. H2 storage Mg nanoparticles are a promising candidate for efficient H2 storage. Li-ion batteries Using NP's in batteries improves charging time and the lifetime of the battery. Health Anti-microbial coatings Incorporating silver MNP's in fabrics makes the fabric anti-bacterial, a procedure that is relatively easy to do with spark discharge. Cancer treatment MNP's are being used in research for new cancer drugs and to improve chemotherapy. In-vivo imaging NP's can be used for medical imaging, as contrasting agents in MRI or other techniques. Toxicology Testing the toxicology of nanoparticles can be made faster and easier using spark discharge. Above table based on data searches using Scopus.

From research to commercial applications

Examples of direct applications of nanoparticles include improved drug delivery systems at the cellular level in medicine; improved battery power and function; and improved materials development. (The use of nanoparticles to improve/increase/provide adhesivity of different materials for wider and cheaper availability of resources.) While the possible applications of nanoparticles are nearly unlimited, commercial applications are limited by the lack of extended knowledge of the quantum properties of nanoparticles and the limitations in the scale-up capabilities of current production methods.

Gas phase production of nanoparticles

History of the technology (spark ablation)/machine.

How it works (the process)

Working with nanoparticles (theory, uses, unknowns)

What kind of research has been (and currently) done, using this type of spark generator

(ask TC how to mirror the Technology page of VSP website)

The technology behind VSP-G1

Literature

A compiled list of literature applicable to VSP-G1's technology and applications. Set up to open in new window

Health Council of the Netherlands. Health significance of nanotechnologies. The Hague: Health Council of the Netherlands, 2006; publication no. 2006/06E. Available online. Set up to open in new window

Hoeneveld, D. et al. Nanosafety Guidelines. Delft University of Technology: NanoSafety workgroup of the Faculty of Applied Sciences, 2008. Available as downloaded document. Set up to open in new window

Detailed communication set up

Configurations

Command syntax

Command list

VSP-G1 Technical specifications

Unit Specifications

Power 110-240V AC Dimensions Casing ca. 52x30x20cm Reactor added height ca. 10cm Weight 19kg Gas inlet/outlet 10mm tubes (with Swagelok connectors) Display 16x2 characters Digital output RS232

Operating Window

Flow rate 1-30 L/min Gas Supported: Ar or N2 (recommended purity 5.0)

Unsupported: He, Ne, Xe, Kr

Contact VSParticle for the use of reactive gases such as air and H2.Electrode material Comes with Cu electrodes.

Various other metals (e.g. Ag, Au, Pt, W, Ni), semiconductors and carbon are possible.Primary particle size 1 atom to 20 nm Ablation rate ~0.01-100 mg/h (material dependent) Typical particle concentration 108-1011 cm-3

EC Declaration of Conformity

Warranty

edited by Kate Groves 12:06, 29 September 2016 (CEST)